ACM is home to several highly automated, high volume machining lines. ACM is able to turn parts in the 250mm-350mm size range with a burnished or ground finish. We can provide assembled parts as needed. ACM has a full service quality lab that includes 3D scanning, Coordinate and Roundness Measuring Machines (CMM and RMM respectively) and surface roughness measuring equipment. The ACM machining department is home to a dedicated fluids management team, tool preset area and machine shop. Our machining engineering team developed a patented system (no. 14/669,346) that reduced the need for paper media within the pad finishing grinding operation. This reduction helped to minimize our environmental impact. Our in-house machining engineering group installs new machines, processes, technologies, and automation to ensure future cost competitiveness.

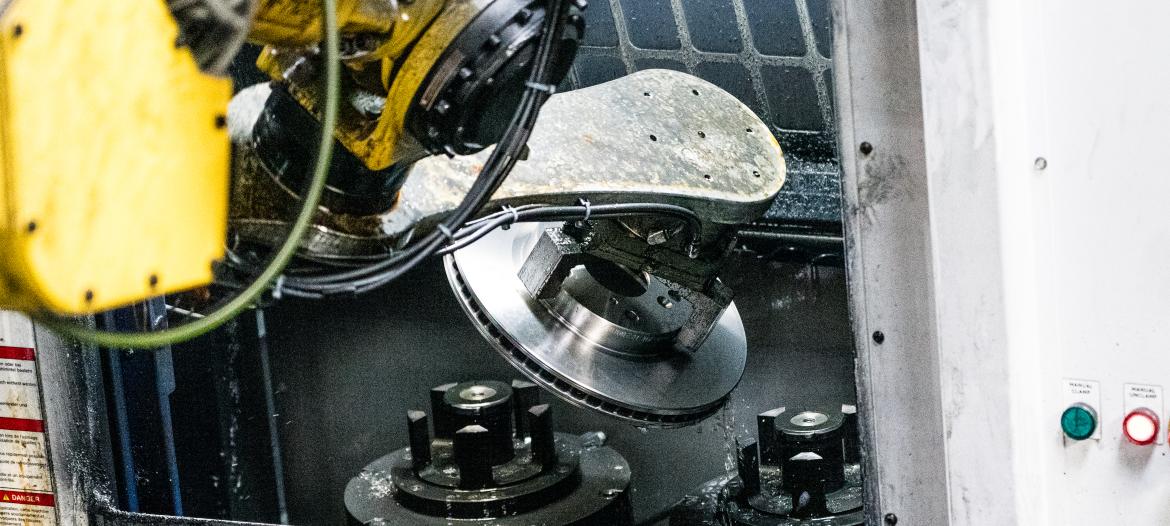

ACM machining lines include machining centers with Fanuc CNC controls. The machine is typically loaded with a robot or a loader system. Quick change tooling and part holding systems are used to minimize downtime for model changes. The machines are equipped with error proofing methods for part type, broken tool detection and part sensing to ensure part quality. All rotors are inspected 100% for critical characteristics such as balance, runout, thickness variations, and surface profiles. Automated pack out cells are used to ensure consistency and are flexible for multiple model types.