ACM has four foundry lines, two located in Michigan and two in Georgia. From core production to a finished product, ACM has the ability to make up to 11,000 metric tons per month between our facilities. ACM has state of the art metal lab equipment that is able to confirm the high quality of our parts with image analysis for grey and ductile iron, Rockwell hardness, carbon analysis testing and x ray capability. Our sand lab is capable of 24 hour monitoring of sand conditions. In addition ACM is able to simulate pour conditions to optimize the quality of our parts.

ACM has four foundry lines, two located in Michigan and two in Georgia. From core production to a finished product, ACM has the ability to make up to 11,000 metric tons per month between our facilities. ACM has state of the art metal lab equipment that is able to confirm the high quality of our parts with image analysis for grey and ductile iron, Rockwell hardness, carbon analysis testing and x ray capability. Our sand lab is capable of 24 hour monitoring of sand conditions. In addition ACM is able to simulate pour conditions to optimize the quality of our parts.

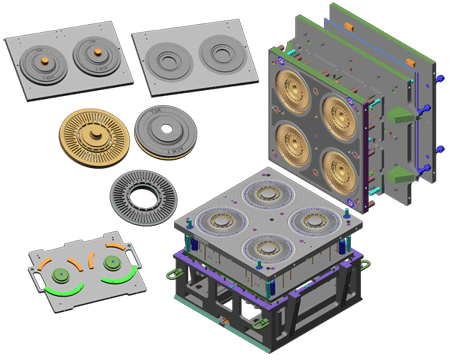

Our Sand Core production is located in our Georgia facility. Utilizing two 60 liter machines ACM can make cores up to 900mmx900mmx200mm. Automated cells are used to ensure consistency and are flexible for multiple model types.

Our Michigan facility boasts a horizontal Georg Fischer. This line can produce parts up to 810mmx660mmx200// with (2) 4-Ton electric melters where the iron is manually poured into a horizontal cope and drag impact line. The parts are then sent through a Didion Separator and a batch shot blast machine before reaching the end of line for inspection where our associates carefully inspect each part.

The remainder of the casting lines are Disa machines, one in Michigan and two in Georgia, which are able to produce a parts up to 950mmx700mmx650mm. Michigan has (2) 9 Metric ton melters and utilize autopouring into a vertical mold machine. Georgia has two vertical lines utilizing (4) 10-Ton electric melters and a 20 Ton pressure pour. The parts are then sent thorough a continuous blast machines before reaching final inspection to be carefully inspected before packing.